Bringing a new electronic product to market is a race against time. From the initial concept to the final launch, every step needs to be efficient and precise. A critical stage in this journey is developing the core electronics, which often requires a unique solution tailored to the product’s specific needs. This is where custom printed circuit board assembly (PCBA) becomes essential. A forward-thinking PCBA manufacturer that offers custom solutions along with rapid prototyping can dramatically shorten development timelines and ensure a product is ready for success.

What is Custom PCBA Manufacturing?

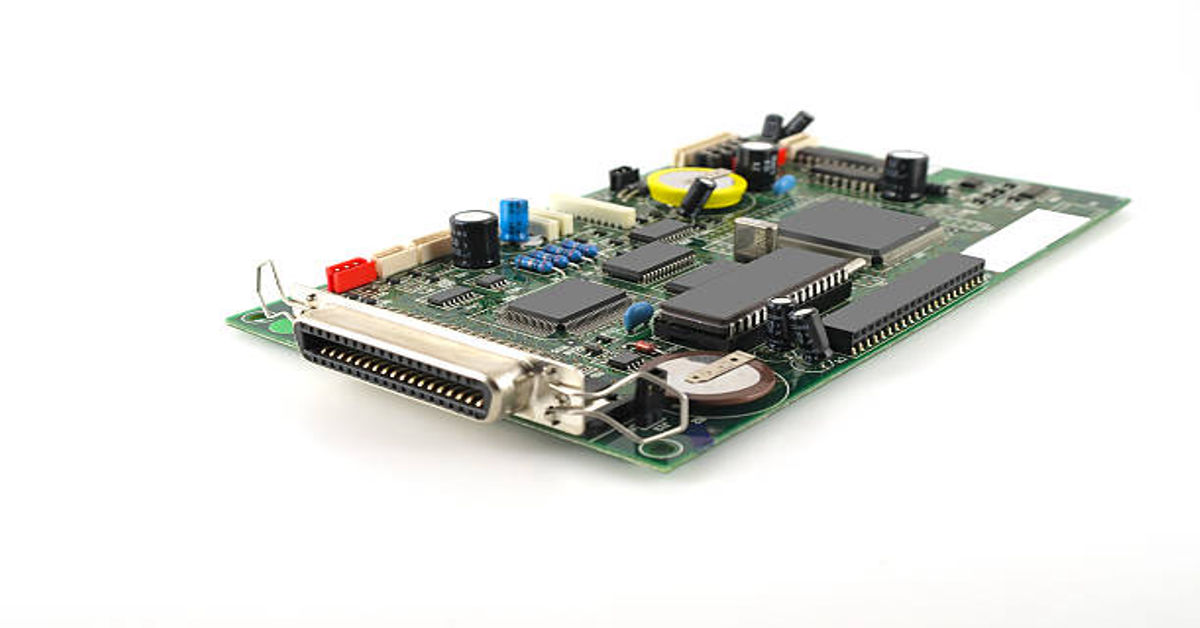

Standard, off-the-shelf circuit boards work for many basic applications, but they rarely fit the unique requirements of an innovative new product. Custom PCBA manufacturing is the process of creating a circuit board assembly designed specifically for one device. This involves creating a unique PCB layout, sourcing specific components, and using a tailored assembly process to meet exact size, shape, and functional specifications.

Think of it like the difference between buying a suit off the rack and getting one custom-tailored. The off-the-rack suit might fit okay, but the tailored one is designed for a perfect fit, better comfort, and a sharper look. In the same way, a custom PCBA ensures optimal performance, fits perfectly within the product’s enclosure, and includes only the necessary features, which can also help control costs.

Why Customization is Crucial for Innovation

- Optimized Performance: A custom board is engineered to support the product’s functions perfectly, eliminating performance bottlenecks that can occur with generic boards.

- Perfect Fit and Form Factor: New products, especially in consumer electronics, often have unique shapes and size constraints. Custom PCBAs are designed to fit into these specific enclosures.

- Feature Integration: You can integrate all necessary technologies, from Bluetooth to specific sensors, directly onto one board, creating a more efficient and reliable device.

- Cost Efficiency: By including only the components you need, you avoid paying for unnecessary features found on pre-made boards, leading to lower per-unit costs in mass production.

The Power of Rapid Prototyping in PCBA

An idea for a custom PCBA is just the beginning. Before committing to thousands of units for mass production, you must test the design. This is where rapid prototyping comes in. It is the process of quickly producing a small number of functional PCBAs based on a new design. These prototypes allow engineers to test, validate, and refine their concepts in a real-world setting.

A PCBA manufacturer with strong rapid prototyping capabilities acts as a development partner, helping you move from design to a physical, testable board in days rather than weeks or months.

How Rapid Prototyping Accelerates Development

The traditional product development cycle could be slow and linear. You would design a board, send it for a full production run, and only then discover potential flaws. This was expensive and time-consuming. Rapid prototyping introduces an agile, iterative approach.

- Design and Test Quickly: Engineers can get a physical prototype in their hands fast. They can immediately begin testing its functionality, fit, and performance.

- Identify Flaws Early: Does the board overheat? Is a connection point too weak? Does it fit correctly in the casing? Prototyping reveals these issues at the earliest, least expensive stage.

- Iterate and Improve: Based on test results, engineers can quickly revise the design. A new prototype can be produced to validate the fixes. This cycle of “build, test, learn” can be repeated multiple times in a short period, leading to a much more robust final design.

- Reduce Financial Risk: Finding a major design flaw after ordering ten thousand units can be a financial disaster. Prototyping minimizes this risk by confirming the design’s viability with a small, low-cost run first.

Key Benefits of Combining Custom Manufacturing and Prototyping

When a PCBA manufacturer offers both custom assembly and rapid prototyping under one roof, it creates a seamless and powerful workflow for product developers.

A Smoother Path from Concept to Production

Working with a single partner eliminates the friction of moving from a prototype shop to a mass production facility. The manufacturer is already familiar with your design’s intricacies from the prototyping phase. They can provide valuable Design for Manufacturability (DFM) feedback early on, ensuring your prototype is not just functional but also optimized for efficient, large-scale production.

Ensured Quality and Consistency

The same quality control standards, equipment, and expertise used for the final production run are applied to your prototypes. This means your prototype is a true representation of what the final product will be. Inspections like Automated Optical Inspection (AOI) and X-ray Inspection can be used on prototypes to catch subtle defects, ensuring the refined design is flawless before it scales.

Faster Time-to-Market

This integrated approach is the fastest way to get a product into customers’ hands. The rapid iteration cycle allows you to finalize your design sooner. The smooth transition from the final prototype to full production means manufacturing can begin almost immediately after the design is approved. This speed can be a decisive advantage in a competitive marketplace.

Your Partner in Innovation

In the world of electronics, speed and precision are everything. Custom PCBA manufacturing allows you to build a product that is perfectly tailored to its purpose. Adding rapid prototyping to the mix transforms the development process, making it faster, more flexible, and less risky. By choosing a PCBA manufacturer that excels in both, you are not just sourcing a component; you are gaining a strategic partner dedicated to helping you innovate effectively and bring a superior product to market ahead of the competition.