Table of Contents

- Introduction

- Shock Absorption and Floor Protection

- Even Weight Distribution

- Suitability for Indoor and Outdoor Use

- Material Composition and Floor Safety

- Applications in Various Industries

- Maintenance Tips for Optimal Performance

- Conclusion

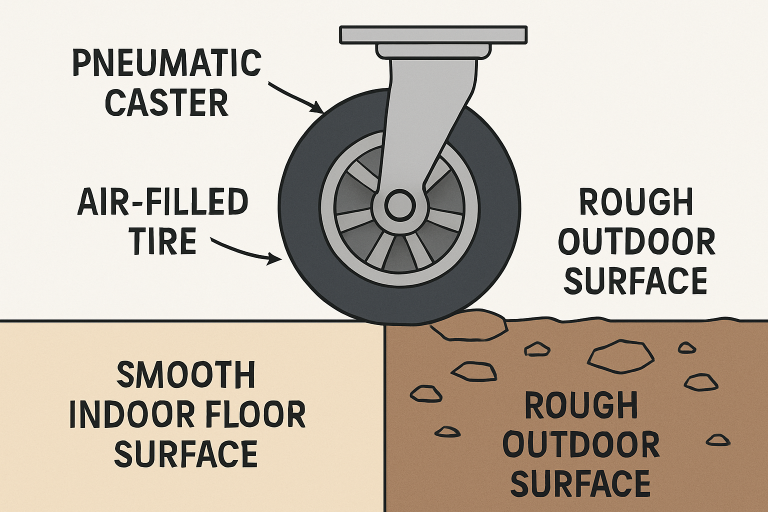

Whether managing warehousing, event production, or industrial logistics, the right equipment makes a crucial difference in operational efficiency and facility protection. For companies navigating between indoor showrooms and outdoor staging environments, pneumatic casters are an essential component for preserving flooring surfaces while ensuring high mobility. Their advanced design, featuring air-filled tires, sets them apart for delicate surface applications, enabling professionals to move heavy loads across a variety of terrains without damaging floors.

Pneumatic casters excel in minimizing wear and tear, offering benefits like shock absorption and non-marking tread that other wheels can’t match. This makes them ideal for environments where floor aesthetics and surface integrity are crucial, such as hospital corridors, retail spaces, factory floors, and sports facilities. Their suitability for both indoor and outdoor applications, coupled with their capacity to handle diverse surfaces, demonstrates their versatility for modern operations.

Shock Absorption and Floor Protection

Pneumatic casters are engineered with air-filled tires, adding a unique layer of cushioning that absorbs shocks and vibrations during movement. This ability is crucial when transporting sensitive loads—such as laboratory equipment, medical devices, or valuable display items—across hard, indoor floors that are prone to dents or scratches. The shock-absorbing function of pneumatic casters not only protects the items being transported but also significantly reduces the chances of permanent flooring damage, ensuring surfaces look pristine and retain their value over time. This is especially critical in institutions and organizations where facility appearance and floor safety are stringent priorities.

Even Weight Distribution

Unlike traditional caster wheels that often lead to floor indentations and localized stress, pneumatic casters distribute load weight more evenly. Their larger, softer profile creates a broader contact patch, which lowers point pressure across all flooring types, including hardwood, vinyl, and tile. This feature is crucial for operations in hotels, museums, and commercial spaces where excessively concentrated weight can lead to lasting floor damage and costly repairs. According to Buildings.com, preventing concentrated loads is among the top recommendations for maintaining the longevity of commercial floors.

Suitability for Indoor and Outdoor Use

Pneumatic casters are designed for seamless transition between different environments, making them the preferred solution for businesses that need to move items from pristine indoor environments to uneven outdoor terrains. Their thick, air-filled treads easily roll over surfaces such as gravel, turf, pavement, or concrete, with minimal risk of scuffs or chips on the floor during indoor use. This dual compatibility is why they are frequently found in warehouse loading docks, event centers, and other areas where versatile movement without compromising the floor is required.

Choosing the right caster isn’t just about surface compatibility; it’s also about efficiency and operational flow.

Material Composition and Floor Safety

The soft rubber tire of a pneumatic caster provides natural cushioning and ensures non-marking performance, crucial for settings where aesthetics and cleanliness are essential. Unlike polyolefin or steel wheels, which often scratch, groove, or mark floors, pneumatic casters glide softly over surfaces, drastically reducing any trace of movement. This makes them indispensable in medical facilities, corporate venues, and grocery stores, where slip resistance and spot-free floors are part of daily safety and cleanliness protocols. The gentle rubber tread is also less likely to accrue debris that could otherwise scratch or degrade floor finishes, supporting maintenance of high hygiene standards.

Applications in Various Industries

Across various sectors, pneumatic casters have a notable impact on both floor protection and the mobility of goods and equipment. In aerospace manufacturing, for instance, significant parts need to be transported from hangars to runways and sensitive equipment moves between laboratories and outdoor test sites—all operations that benefit from floor-safe, shock-absorbing wheels. Event production companies also rely on pneumatic casters for quick stage assembly in areas with changing surfaces. In healthcare and hospitality settings, these casters prevent disruption to both the flooring and the facility’s peace by ensuring quiet, gentle movement.

Maintenance Tips for Optimal Performance

Ensuring pneumatic casters provide long-lasting floor protection requires consistent maintenance. Here are some tips:

- Regular Inspections: Frequently check tires for proper air pressure and look for wear, flats, or cracks that can indicate reduced shock absorption.

- Debris Management: Clean casters and tires regularly to prevent any trapped dirt or grit from scratching indoor floors when casters transition from outdoors.

- Lubricate Swivels: Keep the swivel joints and bearings well-lubricated to ensure the wheels turn smoothly, preventing drag that can scrape the floors.

- Obey Load Limits: Never exceed the recommended load capacity, as overloading puts extra stress on both casters and flooring, increasing the likelihood of damage.

Conclusion

Pneumatic casters offer significant value for operations that require both robust mobility and premium flooring protection in multi-environment settings. Their exceptional shock absorption, broad weight distribution, and non-marking design make them the industry standard for safeguarding floors during the movement of goods and equipment. Maintaining pneumatic casters through routine checks and thoughtful use extends their lifespan, maximizes facility appearance, and reduces unplanned maintenance costs, all while supporting high standards of operational efficiency.