When upgrading steering components for heavy-duty trucks, off-road rigs, or lifted vehicles, one product often recommended is the HD crossover steering kit. For enthusiasts who use their vehicles in rugged environments, tackle steep climbs, or haul heavy loads, factory steering setups often fail to deliver precision, durability, and control. This is where a heavy-duty crossover steering system comes into play, offering enhanced reliability, stability, and strength.

This article provides a comprehensive breakdown of the HD crossover steering kit, covering design principles, benefits, installation details, compatibility, performance improvements, common issues, and maintenance practices. Whether you are a mechanic, an off-road enthusiast, or a truck owner seeking a long-term upgrade, this guide will help you fully understand the value of investing in a crossover steering system.

1. Understanding Steering Systems

To appreciate the benefits of a crossover steering kit, it’s important to first understand how steering works in heavy-duty vehicles.

Factory Steering Setup

Most trucks and SUVs come equipped with a traditional inverted-Y steering design. In this configuration, the drag link connects from the pitman arm (on the steering box) down to the tie rod. While effective for stock vehicles, this setup becomes problematic when:

- Suspension lifts are installed (changing steering geometry).

- Larger tires are added (increasing strain).

- Off-road articulation is required (causing binding).

The factory setup often results in bump steer, poor alignment retention, and accelerated wear on tie rods.

Crossover Steering Concept

The crossover steering design moves the drag link so it runs directly from the pitman arm to the passenger-side steering knuckle instead of attaching to the tie rod. This adjustment:

- Creates a more natural steering angle.

- Reduces bump steer.

- Improves leverage and control.

- Increases strength and durability for demanding conditions.

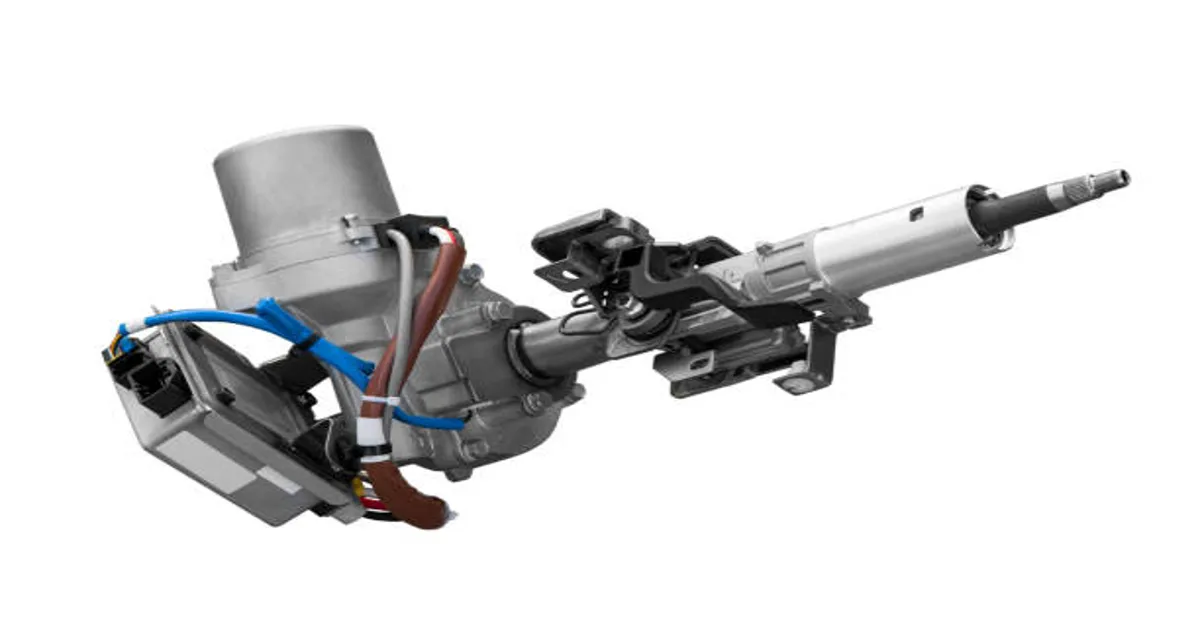

2. What is an HD Crossover Steering Kit?

An HD crossover steering kit is a heavy-duty upgrade that replaces factory steering linkage with stronger components, specifically designed for lifted or off-road vehicles.

Core Components

A typical kit includes:

- Heavy-duty drag link (direct pitman arm to passenger knuckle).

- Heavy-duty tie rod (connects both steering knuckles).

- Forged steel rod ends or heim joints for articulation.

- High-strength tubing (DOM or solid bar stock).

- Mounting hardware for direct installation.

Key Characteristics

- Thicker steel construction (commonly 1.5″ OD, .250 wall tubing).

- Larger rod ends (1-ton applications often use GM 1-ton tie rod ends).

- Engineered geometry (optimized for lifted vehicles, often 4–8″ suspension lifts).

- Bolt-on design (minimal welding, mostly direct fit).

3. Why Choose HD Crossover Steering?

Investing in a crossover kit provides both practical benefits and performance advantages.

Benefits

| Feature | Stock Steering | HD Crossover Steering |

|---|---|---|

| Strength | Moderate, thin tubing | Extra-thick tubing, 1-ton ends |

| Steering Geometry | Prone to bump steer | Optimized angles for lifts |

| Durability | Wears quickly under stress | Long-lasting heavy-duty joints |

| Off-Road Capability | Limited articulation | Full articulation without binding |

| Tire Compatibility | Best for stock sizes | Handles oversized 35″+ tires |

Practical Advantages

- Smoother steering at highway speeds with big tires.

- Reduced play in the steering wheel.

- Improved vehicle tracking off-road.

- Safer operation when towing heavy loads.

- Increased lifespan of steering components.

4. Applications and Compatibility

HD crossover steering kits are commonly used on:

- Jeep Wrangler, Cherokee, and Gladiator builds.

- GM, Dodge, and Ford 4×4 trucks.

- Off-road buggies and rock crawlers.

- Lifted daily drivers with oversized tires.

Compatibility Considerations

- Axle type: Most kits are designed for Dana 44, Dana 60, or GM 1-ton axles.

- Lift height: Usually required for vehicles lifted 4 inches or more.

- Pitman arm: A flat or drop pitman arm may be needed.

- Wheels & tires: Clearance must be checked for tie rod placement.

5. Installation Guide

Installing a crossover steering kit requires mechanical skill, proper tools, and attention to detail. While many enthusiasts perform the installation themselves, professional installation is recommended for safety.

Tools Required

- Torque wrench.

- Pickle fork or ball joint separator.

- Drill (for knuckle reaming if needed).

- Jack stands and hydraulic jack.

- Hand tools (sockets, wrenches).

Step-by-Step Process

- Prepare the vehicle – Park on level ground, secure with jack stands, and remove front wheels.

- Remove factory steering components – Detach drag link, tie rod, and related hardware.

- Inspect knuckles and pitman arm – Ensure bores are clean and ready for new rod ends.

- Install new tie rod – Connect both knuckles using heavy-duty tie rod.

- Install drag link – Attach directly from pitman arm to passenger knuckle.

- Tighten and torque – Secure all hardware to manufacturer specifications.

- Check clearances – Ensure no contact with sway bars, track bar, or frame.

- Alignment – Professional alignment recommended for proper tracking.

6. Performance Results

After installation, users often report:

- Elimination of bump steer.

- Smoother steering input at highway speeds.

- Improved turning radius with larger tires.

- Reduced wear on ball joints and suspension parts.

For off-road vehicles, the difference is night and day—better climbing, stability on uneven terrain, and reliability under extreme articulation.

7. Maintenance of HD Crossover Steering Kits

Though built to last, maintenance ensures long service life.

Regular Checks

- Grease all rod ends during oil changes.

- Inspect for loose hardware.

- Check for tie rod end play.

- Verify alignment after major off-road trips.

Lifespan

A quality kit can last 100,000 miles or more with proper maintenance, even under heavy off-road use. Cheap alternatives often fail quickly, so investing in reputable brands is crucial.

8. Common Issues and Troubleshooting

While rare, some issues can arise if installation or vehicle setup is not correct.

| Issue | Possible Cause | Solution |

|---|---|---|

| Steering feels loose | Rod ends worn | Replace with new ends |

| Tires rub tie rod | Improper wheel backspacing | Use wheels with more offset |

| Vehicle pulls to one side | Misalignment | Perform professional alignment |

| Binding at full turn | Incorrect pitman arm or knuckle ream | Adjust setup for clearance |

9. Cost Considerations

The cost of an HD crossover steering kit varies based on axle type, material, and brand.

| Kit Type | Price Range |

|---|---|

| Basic HD Tie Rod Upgrade | $250 – $400 |

| Full Crossover Kit (Tie Rod + Drag Link) | $500 – $900 |

| Premium 1-Ton Steering Systems | $1000 – $1500 |

While the initial investment may seem high, the long-term savings on repairs, alignment issues, and safety improvements make it worthwhile.

10. Choosing the Right Kit

When selecting a kit, consider:

- Vehicle usage – Daily driver, off-road, towing?

- Axle type – Dana 44, 60, or custom application?

- Budget – Economy kits vs. premium forged systems.

- Future upgrades – Planning bigger tires or more lift?

- Ease of installation – Bolt-on kits vs. welding required.

11. Expert Tips for Best Performance

- Pair the kit with a heavy-duty track bar for balanced steering geometry.

- Use greaseable tie rod ends to extend service life.

- Consider hydro-assist steering if running 40”+ tires.

- Recheck torque after first 500 miles of installation.

- Always get a professional alignment for best handling.

Final Thoughts

The HD crossover steering kit is one of the most impactful upgrades for any lifted or off-road vehicle. By correcting steering geometry, improving durability, and eliminating common factory flaws, it transforms how a truck or SUV handles both on and off the road.

For drivers who want confidence, safety, and reliability, the investment in a quality crossover steering system pays off over years of hard use. Whether you are rock crawling, hauling heavy loads, or simply running 37-inch tires on your daily driver, this upgrade ensures your vehicle’s steering is as tough as the terrain you tackle.

ALSO READ: The Complete Guide to Eschopper: Technology, Benefits, and Future of Eco-Friendly Cruising

FAQs

Q1. What is the difference between crossover steering and factory steering?

Factory steering uses an inverted-Y design prone to bump steer with lifts, while crossover steering provides direct linkage for improved geometry.

Q2. Do I need an HD crossover steering kit for a stock truck?

Not usually. Stock trucks handle fine with factory components, but once you add large tires or lifts, an upgrade is beneficial.

Q3. Can I install a crossover steering kit myself?

Yes, if you have proper tools and experience. However, professional installation and alignment are highly recommended.

Q4. How often should I grease the rod ends in an HD steering kit?

Typically, during every oil change or after intense off-road use, depending on dust, mud, and water exposure.

Q5. Will a crossover steering kit work with my Dana 44 axle?

Yes, many kits are designed for Dana 44 and Dana 60 axles, but always confirm compatibility before purchase.