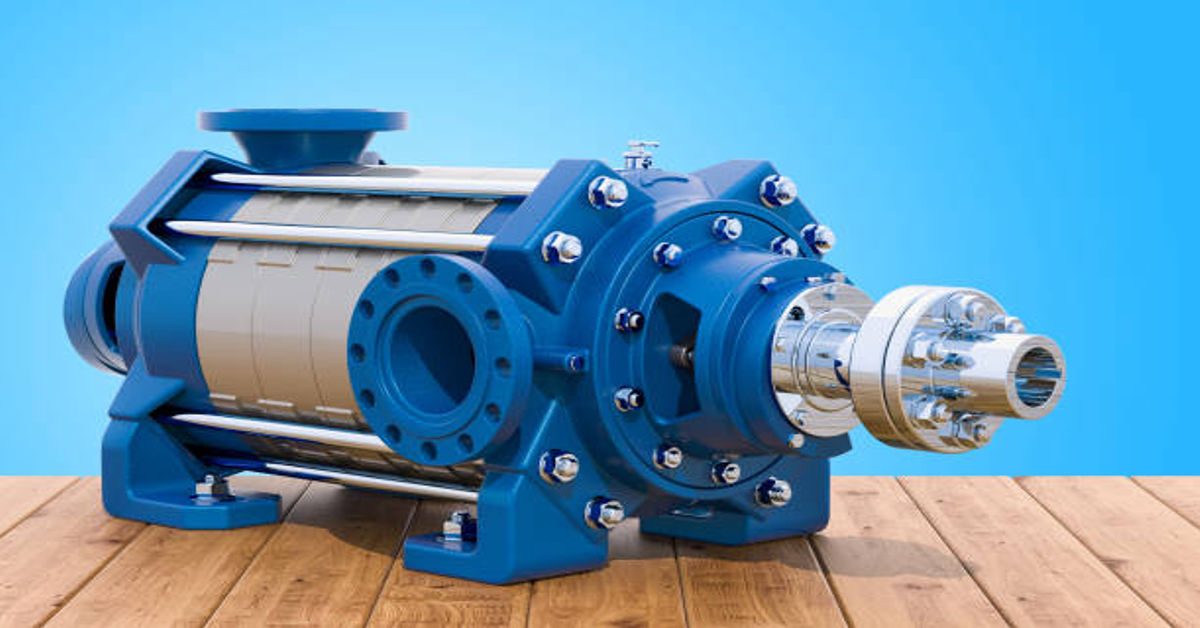

An iron pump is a mechanical device primarily used to move liquids, often containing impurities or exhibiting corrosive properties, from one location to another. These pumps are widely constructed from cast iron, a material renowned for its strength, durability, and cost-effectiveness. Cast iron provides exceptional resistance to wear, making it ideal for industrial, agricultural, and municipal applications. Iron pumps are essential in a wide range of sectors, including water supply, wastewater management, chemical industries, irrigation systems, and heavy-duty manufacturing processes.

This article provides a detailed exploration of iron pumps, their types, operational principles, advantages, limitations, maintenance strategies, selection criteria, and practical applications. By the end, readers will gain a thorough understanding of why iron pumps remain a cornerstone of fluid-handling technology across industries worldwide.

1. Introduction to Iron Pumps

Pumps have been integral to human civilization for centuries, initially employed for irrigation, water transport, and drainage. Modern iron pumps combine classic mechanical engineering principles with advanced materials and manufacturing techniques to provide reliable and efficient fluid movement.

Cast iron is chosen for these pumps because it offers:

- High compressive strength suitable for heavy workloads.

- Excellent wear and abrasion resistance.

- Cost efficiency compared to stainless steel or alloy alternatives.

- Adequate corrosion resistance, especially when coated or lined for specific applications.

Iron pumps are typically centrifugal or positive displacement types, each with distinct design principles suited for different operational needs.

2. Working Principle of Iron Pumps

An iron pump works by converting mechanical energy from a motor or engine into kinetic energy in the fluid. The process varies depending on the pump type:

- Centrifugal Pumps:

These pumps use a rotating impeller to impart velocity to the liquid, which is then converted into pressure. Cast iron centrifugal pumps are ideal for high-flow, low-viscosity liquids, such as water or wastewater. - Positive Displacement Pumps:

These pumps move a fixed volume of liquid per rotation or stroke, making them suitable for high-viscosity liquids or applications requiring precise dosing. Common types include gear pumps, piston pumps, and diaphragm pumps.

Key Features of Iron Pumps:

- Durable housing capable of handling abrasive fluids.

- Seals and gaskets compatible with the pumped medium.

- Mechanical drive or motor connection for energy input.

| Component | Function |

|---|---|

| Pump Casing | Houses the impeller and fluid pathway; provides pressure containment. |

| Impeller / Rotor | Converts mechanical energy into fluid movement. |

| Shaft | Transmits power from motor to impeller. |

| Seal | Prevents leakage of fluid along the shaft. |

| Inlet / Outlet | Allows fluid to enter and exit the pump efficiently. |

3. Types of Iron Pumps

Iron pumps can be broadly categorized based on their mechanism and application.

A. Centrifugal Iron Pumps

These are the most common type of iron pumps. They operate on the principle of centrifugal force and are ideal for water, sewage, and chemicals with low viscosity.

Subtypes:

- Single-stage centrifugal pumps: Suitable for moderate flow and pressure applications.

- Multi-stage centrifugal pumps: Used for high-pressure systems, such as boiler feedwater and industrial pipelines.

B. Gear Pumps

Gear pumps are positive displacement pumps where fluid is transported between two intermeshing gears. Cast iron gear pumps are robust and can handle viscous fluids like oils, fuels, and chemicals.

C. Piston and Plunger Pumps

These pumps use a reciprocating piston to move liquid. Iron construction allows them to withstand high pressures, making them suitable for hydraulic systems, chemical processing, and high-pressure washing.

D. Diaphragm Pumps

Diaphragm pumps utilize a flexible membrane to displace fluid. Iron pumps with diaphragm mechanisms are excellent for corrosive, abrasive, or slurry liquids, providing leak-free operation.

E. Submersible Iron Pumps

Designed for full immersion in liquids, submersible iron pumps are used in sewage treatment, drainage systems, and flood control, providing quiet and reliable operation.

| Pump Type | Mechanism | Common Applications |

|---|---|---|

| Centrifugal | Rotating impeller | Water supply, wastewater, chemical transfer |

| Gear | Intermeshing gears | Oils, fuels, viscous chemicals |

| Piston / Plunger | Reciprocating piston | High-pressure systems, hydraulic fluids |

| Diaphragm | Flexible membrane | Abrasive or corrosive liquids |

| Submersible | Electric motor-driven, submerged | Sewage, drainage, flood control |

4. Material Advantages of Cast Iron in Pumps

Cast iron provides a unique combination of mechanical strength, wear resistance, and cost-efficiency.

Advantages:

- Durability: Handles high loads and pressure without deformation.

- Abrasion Resistance: Withstands solid particles in slurry or wastewater.

- Corrosion Resistance: Resistant to mild chemical corrosion; can be coated for enhanced protection.

- Thermal Stability: Maintains performance across temperature variations.

- Cost-Effectiveness: Cheaper to manufacture than stainless steel or bronze equivalents.

Limitations:

- Cast iron can be brittle under impact loads.

- Not suitable for highly acidic or strongly oxidizing fluids unless lined.

- Heavier than alternative metals, requiring sturdy foundations.

| Property | Cast Iron Pump | Stainless Steel Pump |

|---|---|---|

| Corrosion Resistance | Moderate | High |

| Cost | Low | High |

| Durability | High | Very High |

| Abrasion Resistance | Excellent | Moderate |

| Weight | Heavy | Lighter |

5. Applications of Iron Pumps in Industry

Iron pumps are widely used across industries due to their versatility, durability, and economic value.

A. Water and Wastewater Management

- Pumping clean water from reservoirs.

- Wastewater transport in municipal sewage systems.

- Slurry and sludge handling in treatment plants.

B. Chemical Industry

- Handling mild acids, alkaline solutions, and industrial chemicals.

- Dosing and metering fluids with gear or piston pumps.

C. Agriculture

- Irrigation systems, including high-volume field watering.

- Fertilizer and slurry distribution in farms.

D. Manufacturing and Process Industry

- Cooling water circulation in machinery.

- Fuel transfer and oil pumping in mechanical processes.

- High-pressure cleaning operations.

E. Mining and Construction

- Slurry transport in mining operations.

- Dewatering excavations and construction sites.

| Industry | Application | Preferred Pump Type |

|---|---|---|

| Water Supply | Municipal pipelines | Centrifugal |

| Wastewater | Sludge removal | Submersible / Diaphragm |

| Chemicals | Acid/alkali handling | Gear / Diaphragm |

| Agriculture | Irrigation | Centrifugal / Piston |

| Mining | Slurry pumping | Submersible / Piston |

6. Selection Criteria for an Iron Pump

Selecting the right iron pump is critical for efficiency and longevity. Factors to consider include:

- Fluid Type: Clean water, slurry, chemicals, or viscous liquids.

- Flow Rate and Head: Determines pump size and impeller type.

- Pressure Requirements: High-pressure applications need piston or multi-stage pumps.

- Temperature: Some fluids may require heat-resistant coatings.

- Maintenance Accessibility: Ease of cleaning, inspection, and part replacement.

- Energy Efficiency: Pump selection affects operational cost over time.

| Factor | Key Consideration |

|---|---|

| Fluid Viscosity | High viscosity → positive displacement pump |

| Abrasiveness | Slurry → cast iron with wear-resistant coating |

| Chemical Properties | Corrosive fluids → lined iron or alloy pumps |

| Operating Temperature | Check thermal limits of pump housing |

| Installation Space | Footprint and orientation requirements |

| Cost Efficiency | Balance initial cost with long-term maintenance |

7. Maintenance Practices for Iron Pumps

Proper maintenance ensures optimal performance and extends the service life of iron pumps.

Routine Maintenance:

- Lubrication: Regularly lubricate bearings and moving parts.

- Seal Inspection: Check mechanical seals and gaskets to prevent leakage.

- Impeller Cleaning: Remove debris that can reduce efficiency.

- Vibration Monitoring: Detect misalignment or wear early.

- Water Quality Checks: Prevent sediment accumulation or corrosion.

Periodic Overhaul:

- Dismantle the pump for detailed inspection.

- Replace worn-out impellers, shafts, or seals.

- Reapply protective coatings if required.

| Maintenance Type | Frequency | Purpose |

|---|---|---|

| Lubrication | Monthly | Reduce friction & wear |

| Seal Check | Weekly | Prevent leaks |

| Cleaning | Bi-weekly | Maintain flow efficiency |

| Vibration Test | Quarterly | Detect misalignment |

| Full Overhaul | Annually | Extend pump lifespan |

8. Efficiency and Energy Considerations

Iron pumps can consume significant energy, especially in high-flow applications. Ensuring proper pump sizing, impeller selection, and motor efficiency helps reduce energy costs.

Tips for Efficiency:

- Avoid oversizing pumps; oversized pumps waste energy.

- Maintain impellers free of buildup or corrosion.

- Use variable frequency drives (VFDs) for adjustable flow rates.

- Ensure proper alignment between pump and motor to minimize losses.

9. Advantages of Using Iron Pumps

- Durability and Long Lifespan: Can operate for decades with proper maintenance.

- Cost-Effective: Lower initial investment than stainless steel alternatives.

- Versatility: Suitable for clean water, sludge, slurry, chemicals, and oils.

- High Wear Resistance: Cast iron withstands abrasive fluids efficiently.

- Easy Availability: Components and replacements are widely available.

10. Limitations of Iron Pumps

- Brittleness: Susceptible to shock loads.

- Weight: Heavy construction may require reinforced foundations.

- Corrosion Risk: Not suitable for highly corrosive fluids unless coated.

- Noise: Large iron pumps may produce more operational noise.

11. Common Problems and Troubleshooting

| Problem | Possible Cause | Solution |

|---|---|---|

| Reduced Flow | Clogged impeller | Clean or replace impeller |

| Leakage | Worn seal | Replace mechanical seal |

| Excess Vibration | Shaft misalignment | Realign or balance shaft |

| Overheating | Insufficient lubrication | Lubricate bearings |

| Noise | Air in suction | Check for air leaks and proper priming |

12. Recent Trends in Iron Pump Technology

- Corrosion-Resistant Coatings: Extends lifespan in chemical applications.

- Energy-Efficient Designs: Improved impellers and motors reduce power consumption.

- Automated Monitoring: Sensors detect flow, vibration, and temperature in real-time.

- Compact Designs: Space-efficient pumps for industrial plants.

- Hybrid Materials: Combination of cast iron and polymer linings for extreme environments.

13. Environmental and Safety Considerations

- Proper disposal of wastewater and chemical fluids.

- Leak-proof sealing to prevent environmental contamination.

- Noise reduction and vibration control for occupational safety.

- Energy-efficient pumps to reduce carbon footprint.

14. Cost Analysis of Iron Pumps

| Cost Component | Approximate Range | Notes |

|---|---|---|

| Pump Body | $500–$5,000 | Depends on size & type |

| Motor / Drive | $200–$2,500 | Electric or diesel-driven |

| Installation | $100–$1,000 | Includes piping and fittings |

| Maintenance | $50–$500/year | Lubrication, seals, cleaning |

| Energy Cost | Variable | Depends on flow and usage |

15. Conclusion

Iron pumps are indispensable tools in industrial, agricultural, and municipal applications. Their durability, versatility, and cost-effectiveness make them ideal for handling water, sludge, chemicals, and other fluids. Whether centrifugal, piston, diaphragm, or submersible, iron pumps combine mechanical reliability with robust material strength.

Proper selection, installation, and maintenance are key to maximizing performance and efficiency. With ongoing innovations in energy efficiency, monitoring, and material coatings, iron pumps will continue to be a critical component of fluid handling worldwide. For industries seeking long-term reliability and value, investing in a well-maintained iron pump is a smart decision.

FAQs About Iron Pumps

1. What is an iron pump used for?

Iron pumps are used to move liquids like water, chemicals, oils, and slurry in industrial, agricultural, and municipal applications.

2. What types of fluids can an iron pump handle?

They can handle clean water, wastewater, slurry, mild chemicals, and viscous oils depending on pump type and design.

3. How long does an iron pump last?

With proper maintenance, iron pumps can last 15–25 years or more, depending on operating conditions.

4. Are iron pumps energy-efficient?

Modern designs with variable frequency drives and optimized impellers offer significant energy savings.

5. How do I maintain an iron pump?

Regular lubrication, seal inspection, impeller cleaning, and periodic overhauls ensure long-lasting performance.